Lean 6 Sigma

6 Sigma is a modern business methodology implemented by giant global companies and it aims to eliminate errors, to continuously increase efficiency, profitability and customer satisfaction in business and production processes.

Motorola developed the main principles of the system in 1986, extensively utilizing methodologies such as Quality Control, Total Quality Management and Zero Defect, and pioneers such as Shewhart, Deming, Juran, Ishikawa, Taguchi. Motorola, Honeywell and GE were the first implementers of the system.

Borusan Group has been implementing this methodology since 2002.

With the 6 Sigma methodology - an important aspect of Borusan’s strategic management model, Borusan manages to achieve financial growth and increase in profitability while also realizing a cultural transformation.

6 Sigma practices are conducted by Black Belts who work full-time, who are specialized in this methodology and who supervise the projects and provide training, while Expert Green Belts take part as half-time in the projects. Borusan employees at all levels are also involved in 6 Sigma practices.

As of the end of 2016, a total of 2900 Borusan employees took part in 3300 projects and these projects provided a value of USD 150 million to Borusan.

You may visit the page www.yalin6sigma.com for Lean 6 Sigma Training and Consultancy Services.

What is Lean 6 Sigma?

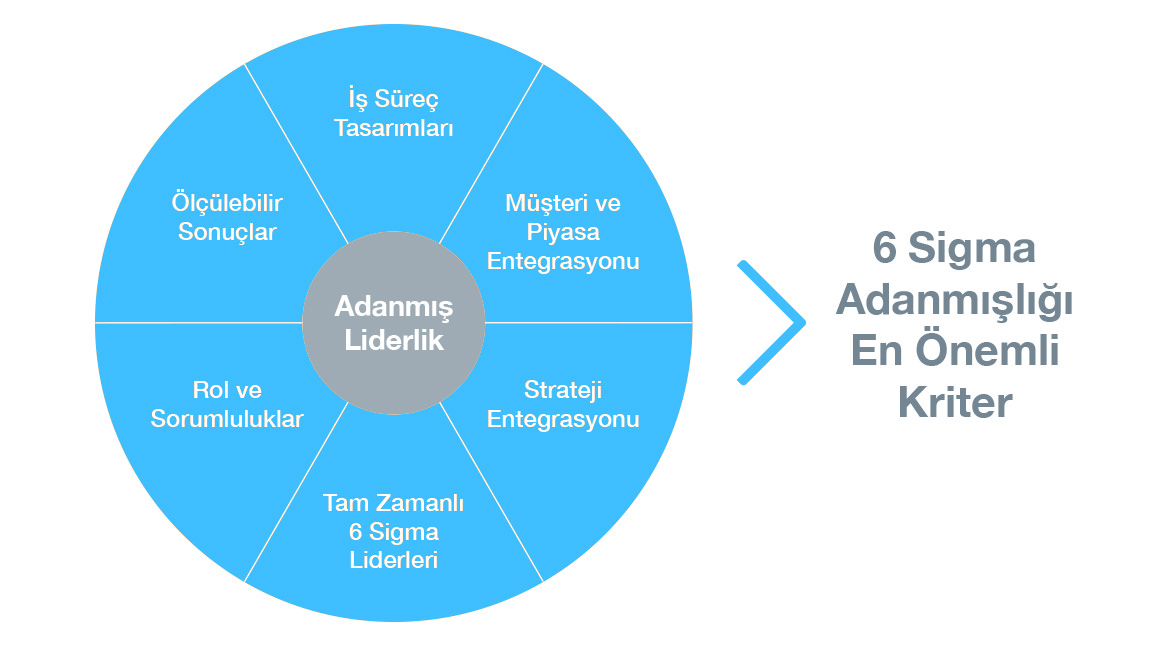

It is a mode of conducting projects, with defined steps and objectives, using quality management and statistics tools, utilizing a certain human resources infrastructure focused on this job in the organization. It aims to increase the quality of the process deliverables by finding and eliminating the sources of error with the support of continuous and determined leadership.

6 Sigma methodology has two main types of projects.

DMAIC works involve the improvement of existing products or processes.

DMEDI projects include the improvement of new products and services.

Lean 6 Sigma at Borusan Lojistik

As Borusan Lojistik Lean 6 Sigma organization, our mission is to;

Extend the understanding of data-based work to the whole company and bring processes that will provide the highest customer satisfaction and company profitability using minimum resources.

Our Lean 6 Sigma success factors to realize our mission are as follows:

| 6 Sigma Links | Sigma Calculator |

|---|---|

| www.isixsigma.com | http://www.isixsigma.com/sixsigma/six_sigma_calculator.asp |

| www.6sigma.us | |

| software.isixsigma.com | |

| www.sixsigmabenchmarking.com |