Innovation

At Borusan Port, we view digital transformation as an integral part of our sustainable value creation processes, and through the digital transformation projects we have implemented, we are taking steps to confidently move our company into the future. The position of digital transformation among our priority sustainability topics highlights its importance in the area of innovation. We have continued to successfully implement new projects during the 2023 operational period without slowing down, adding to those we have already launched. As a result of the digital initiatives at Borusan Port, new digitalization projects have been implemented focusing on transforming processes for increased efficiency, providing benefits to customers, enhancing employee productivity, improving workplace safety, and contributing to the company's sustainability principles.

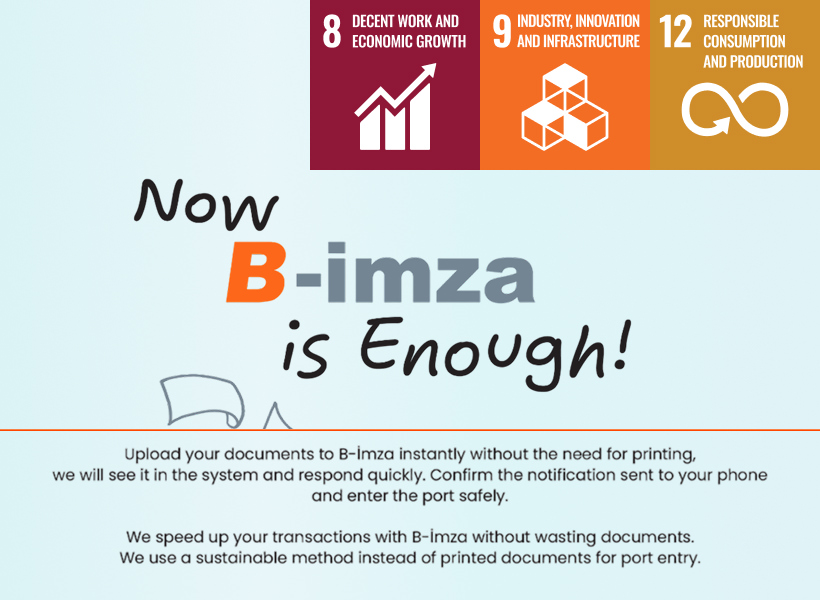

B-Signature Project

The B-Signature project eliminates paper consumption in the process while providing document management for visitors and suppliers entering the port area. Previously, visitors wishing to enter the port had to complete information security and occupational safety agreements via printed copies. With the B-İmza software developed by the Borusan Port IT department, paper consumption has ceased, allowing visitors to enter the port without the need for signatures or waiting, simply by receiving notifications on their mobile phones.

E- Signature Project

This project, implemented in collaboration with Türkkep, was initiated to address the need for numerous employee approvals required by the HR and OHS departments and the challenges associated with archiving these documents. The transition to e-signature has allowed for the instantaneous completion of OHS documents that require regular tracking, as well as improvements in the payroll processes on the HR side, with documents now being archived electronically. As part of the project, all 582 employees have been transitioned to the e-signature application, resulting in an average annual paper consumption reduction of 60,000 sheets.

3D Coil Addressing System Project

The port has implemented a system consisting of in-house software and hardware used for handling rolled sheets in open and closed areas. This system utilizes technologies such as distance-measuring lasers, area scanners, and smart PLC modules, allowing for precise tracking of the three-dimensional location of stacked rolled sheets on-site. The project has reduced time loss caused by manual searching for rolled sheets and transfers, increased workplace health and safety by enabling the on-site workforce to use the computer-based tracking system and minimized errors and energy losses resulting from manual processes.